Density Of Fresh And Hardened Concrete

Specification:

The density of both fresh and hardened concrete is of interest to the

engineer for numerous reasons including its effect on durability, Strength

and resistance to permeability.

Hardened concrete density is determined either by simple dimensional

checks, followed by weighing and calculation or by weight in air / water

buoyancy methods.

Flexure Testing Machine

Specification:

Light weight, rugged high strength frame

Double action hydraulic pump

Self-aligning roller assembly

Hydraulic jack provided with retraction spring

For testing beams of 100 x 100 x 500mm and 150 x

150 x 700mm

Conforms to IS 516, BS 1881 and ASTM C 78 Two

Models are available

Compression And Flexural Testing Machines

Specification:

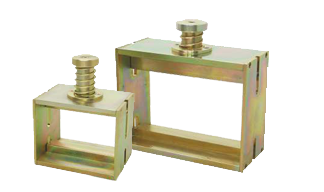

The Labtest series Splitting Tensile Test Devices are accessories for compression machines for measuring the splitting

tensile strengths of ø150 x 300 mm and ø160 x 320 mm cylindrical specimens, 150 mm cube concrete specimens

and of 60-150 mm height x 220 mm length concrete block pavers

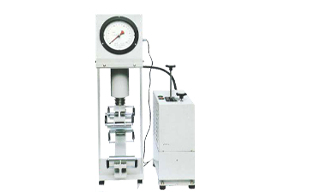

Hand Operated Flexural Testing Machine 250 Kn

Specification:

Ram Diameter (mm) 82

Ram Travel (mm) 50

Pressure Gauge Diameter (mm) 200

Pressure Gauge (in kN) 100

Least Count (in kN) 0.5 Kn

Maximum Pressure (Kgs. /cm) 200

Horizontal Clearance (mm) 210

Vertical Day Light (mm) 160(adj)

Height Of Load Frame (mm) 850

Weight Of Load Frame (Kgs) 150

Lead Screw Yes

Specimen Size (can Be Tested) 0

Flexural Test (size in mm ) 100x100x500

150x150x700

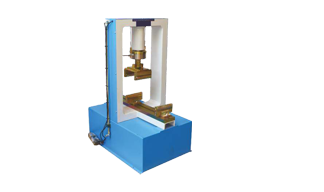

Flexural Frame 100 Kn

Specification:

The versatile load frame is designed for minimum

deflection at maximum load resulting in very high

accuracy. The load frame is welded steel fabrication

carrying the ram fitted to the upper crosshead

Capacity (kn) 100

Class 1 range (kn) 10-100

Resolution 1/65.000

Ram travel (mm) 75

Max. Vert. Test space (mm) 170

Max. Horiz. Test space (mm) 450

Power (w) 750

Overall dimensions 600 x 830 x 1140

(only frame) (mm)

Weight (kg) 180

Semi Automatic Compression Testing Machine

Specification:

The Labtest Semi-Automatic (Motorized) range of 2000 kN and 3000 kN capacity compression testing machines

have been designed for reliable and consistent testing of a wide range of specimens.

Capacity 2000kN

Standard EN

Lower platens dimensions (dia.) 300 mm

Upper platens dimensions (dia.) 300 mm

Maximum vertical clearance between platens 340 mm

Piston diameter 250 mm /

Maximum piston movement 50 mm

Horizontal clearance 360 mm

Power 550 W

Oil capacity 20 L

Maximum working pressure 410 Bar

Dimensions (W x L x H) (mm) 740x500 x970

Fully Automatic Compression Testing Machine

Specification:

High resolution 65.000 points

240 x 120 pixel blue-white graphic lcd display

Standalone full automatic testing capacity

CPU card by microprocessor 32 bit arm risk

architecture

Can make manual tests if required

Large permanent memory up to 256 test results

Rs232c (optional ethernet) connection at 57600 band

One RS232 serial port for connecting either PC or

printer for data transmission

Two analogical channels, use for load cell or pressure

transduce

A sample type and dimensions can be entered respect

to the standard

18 key touch membrane keyboard

Easy to operate with 6 main function keys

Language select: English

Can control two frames (Compression & Flexural)

Digital Load Indicator

Specification:

Display : 2 Line alphanumeric display with back light illumination

Range : Load : 0.1 KN to 6000 KN

Set Load (Limit) : 0.1 KN to 6000 KN

Set Pace Rate : 0.1 KN/sec to 99.9 KN/sec

Sample Area : 0.1 cm to 999.9 cm

Accuracy : ± 0.1% of Full Sacle ±1 digit

Relay Logic : ON when Actual Load

Normal / Peak Mode : Selectable from front panel with LED indication of current mode

Peak Detection : Buzzer alarm re-settable from front Reset switch / Rear external contact

Tare Facility (Zero) : Digital Tare using front panel Tare switch

Memory : Non-volatile EEPROM to save settings

Configuration Lock : Jumper on rear terminals to prevent alteration of configuration from front

Serial Output : RS-232 output to interface to PC

Supply : 220 V AC ± 15% @ 50/60 Hz

Dimensions : Front Fascia: 96 x 192 mm Cut Out: 92 x 188 mm

Compression Testing Machine

Specification:

In these load frames “C” channels are used, they are

welded at the top as well as bottom and with stand high

loads. A hydraulic jack is fitted at centre of the base of

the load frame, over which can be fitted lower platen

and spacer block with the help of centering pin. A lead

screw passes through the top of the frame. To the lower

end of this lead screw is fixed the upper platen with

spherical seat for self alignment. The platens are

accurately machined, hardened and polished. The

lower platen grooves to correctly place the specimen.

Note: The platens are normally rectangular on shape,

but no special request square platens or circular platens

can be supplied at an extra cost.

Ranges: 50 kN to 2000 kN