Wet Sieving Apparatus

Specification:

The wet sieving apparatus is used for determining the fineness of fly ash. The

apparatus comprises of a special stainless steel sieve, 0.045 mm opening, a

spray nozzle ø 17.5 mm with 17 holes ø 0.5 mm oriented and spaced to

conform to the standards. Supplied complete with a pressure gauge ø 80 mm

and fittings for connection to the water supply

Mud Balance

Specification:

Designed to find out specific gravities of semi liquids like mud and

other liquids having densities in the range 0.8 to 2.7. It has a

stainless steel bam calibrated specific gravities from 0.8 to 2.7. A

stainless steel cup with lid and overflow vent is fitted on one side of

the beam. A counter weights with cursor slides over the graduated

scale. The beam has a knife-edge at centre which rests in a

fulcrum fitted in the stand. Leveling screws and spirit level are fitted to the stand. Supplied complete with wooden box.

Briquette mould(single)

Specification:

For casting of cement briquettes for tensile strength tests. It is a two part split mould

made of gun metal.

Two thumb screws facilitate easy and quick assembling and dismantling of the mould.

The minimum cross section of the briquettes cast is 25.4 mm x 25.4 mm. Supplied

complete with a steel base plate.

Automatic Cement Compression & Flexure Testing Machines

Specification:

The Automatic range of single testing chamber and double testing chamber compression and flexure testing machines

have been designed for reliable and consistent testing of mortar samples. These compression and flexure testers are

the results of continuous applications and research studies to upgrade the machines with the latest technologies and

conform the current standards in terms of its technical properties taking into account client requirements by using

suitable accessories. These machines also meet the requirements of CE norms for safety and health of the operator.

Compression and flexture jigs, distance pieces, and also removable transparent front-rear safety doors (should be

factory installed) should be ordered separately.

The automatic cement compression and flexure testing machines allow less experienced operators to perform the tests.

Once the machine has been switched on and the specimen is positioned and centered by the help of centering

apparatus.

The automatic cement compression and flexure testing machines consist of very rigid two column single or double

chamber frames, automatic hydraulic power pack with data acquisition and control system.

Power Pack Automatic Hydraulic Power Pack, dual stage, controlled by control panel is designed to supply the required oil to the load frames for loading. Very silent power pack can load the specimen between 50 N/sec to 2.4 kN/sec with an accuracy of ±5%. A Rapid approach pump is supplied as standard. Safety valve (maximum pressure valve) is used to avoid machine overloading.

Motor The motor which drives the dual pump is an AC motor, 380 V, 50-60 Hz, 3 phase, 1 hp and 0.75 kW and it is controlled by motor inverter. The variation in the oil flow is executed with the variation of the rotation speed of the motor.

Distribution Block

A distribution block is used to control the oil flow direction supplied by the dual stage pump, the following parts are

fitted to the distribution block;

a - Solenoid valve

b - Safety valve (maximum pressure valve)

c - Transducer

d - Low pressure gear pump

e - High pressure radial piston pump

Dual Stage Pump The dual stage pump is formed by two groups Low pressure gear pump High pressure radial piston pump. On the dual stage pump, a high delivery, low pressure gear pump is used for rapid approach, while a low delivery, high pressure radial piston pump is used for test execution. The Rapid approach facility shortens the time interval from piston start until the upper platen touches to the specimen. This excellent feature helps to save a lot of time when a large number of specimens are going to be tested.

Oil Tank The tank includes enough oil to fill the mechanism which pushes the ram during the test. The level and oil temperature can be seen on the indicator fitted to the tank. It has 20 L capacity. Hydraulic motor oil, number 46, must be used. Dimensions : 360 x 380 x 900 mm Weight (approx.) : 80 kg Power : 750 W

Control Unit Control Unit is designed to control the machine and processing of data from load-cells and pressure transducers which are fitted to the machine. All the operations of control unit are controlled from the front panel consisting of a 800x480 pixel 65535 color resistive touch screen display and function keys 2 analogue channels are provided for load-cells or pressure transducers.

Tensile Strength Tester (ELECTRICALLY OPERATED)

Specification:

The instrument employs a friction free, accurate, double lever

system, the load being applied by means of sliding weight on

the top lever. The capacity of the units is 900 kgs. After fixing

the briquette in the jaws, the machine is switched on. The sliding

weight slides over the calibrated lever thus applying tension to the specimen. A

micro switch fitted instantly stop the machine on failure of the briquette and on

failure the tensile load is accurately 0.5kg. By means of a marker provided on the

sliding weight to its zero position. Suitable for operation on 230 V, 50 cycles,

Single Phase, A.C. supply. Supplied complete with one brass briquette mould and one base plate.

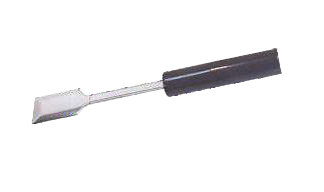

Standard Spatula

Specification:

The standard spatula consists of a steel blade, of a special shape. A

wooden handle is fixed to the stem of blade. The weight does not exceed

340 gms.