Le Chatelier Flask

Specification:

Used for finding specific gravity of hydraulic cement. Made from Borosilicate glass.

The flask is 243mm in total height, having a bulb of 90mm dia of 250ml approximate

capacity. The long neck of the flask has at top a funnel of 50mm dia in that fits a

ground glass stopper. The neck has over-all 11mm i.d. upper portion is graduated

from 18ml to 24ml with 1 ml graduation. Just at the bottom of the neck 1 ml capacity is

marked in between there is 17 ml capacity bulb.

Laboratory Cement Autoclave

Specification:

The autoclave is suitable for conducting accelerated soundness tests on

cements or the autoclave expansion test requiring constant steam pressure

with the correspondent constant pressure. It consists of a stainless steel

cylinder with a welded heat insulated metal housing attractively finished. The

attached control unit encloses a sensitive pressure regulator and pressure

gauge. Power switches and pilot lights for controlling the electric heating

units. Inside chamber dimensions 10.5 cm diameter x 40.5cm height

suitable for operation on 230 V, 50 Hz Single Phase A. C. supply. Supplied

complete with test bar holder, special rack to hold specimens above water

level in the autoclave and in a vertical position to expose them in the same

manner. A Digital PID Controller is fitted for controlling the desired

temperature.

Volume Change Apparatus

Specification:

The apparatus comprises of one mould effective gauge length

complete with base plate, four reference pins, one length

comparator frame, one stainless reference bar with insulated grip,

and one dial gauge, 0.002mm x 5mm

MORTOR MIXER

Specification:

The apparatus consists of an epicyclical type stainless steel paddle imparting

both planetary and revolving motion, by means of gears. It has two speeds of

140 + 5 R.P.M. and 285 +10 R.P.M. With planetary motions of

approximately 62 R.P.M, +5 R.P.M. and 125 R.P.M. +/- 10 R.P.M.

Respectively. The stand of the mixer has arrangement to raise or lower the

bowl. Complete with stainless steel bowl of about six liters capacity. Suitable

for operation on 230 V, 50 cycles, Single Phase A.C, Supply.

Briquette Mould (Three Gang)

Specification:

For casting three cement briquettes at a time for the tensile strength test on cement.

Prism Mould Three Gang

Specification:

It is supplied complete with base. All parts are marked

with the identification number for correct assembly. Each

mould is individually verified in the dimensional

tolerances, hardness, squareness, flatness & roughness.

Size: 40.1 X 40 X 160 mm

Heat Of Hydration Apparatus

Specification:

This equipment is required to determine the heat of hydration of cement as

expressed in calories per gram.

The equipment comprises of the following:

1. A wide mounted double walled vacuum flask with a stop cock 38 mm &

a insulating container for the flask

2. A Beckman thermometer (Range 5° C) held tightly by the cock

stopper in such a way as to avoid accidental contact with the stirrer

blade & the reading lens. To facilitate the easy removal the cock

stopper is in two halves.

3. A constant speed stirrer (double bladed propeller type)extended to

within 38 mm from the bottom of the flask.

4. A funnel (Gooch type) with a stem of 6 mm inner dia & a body approx

25 mm long and 25 mm dia. is fitted to the cock stopper for introducing

the sample

Fully Automatic Mortor Mixer

Specification:

The mixer has been designed to mix mortars and cement

pastes primarily to the requirements of standards. The

mixing paddle has a planetary motion and is driven by a

motor with a microprocessor based speed and preset

programs to meet all listed EN and ASTM standards,

custom designed programs or manual mode. The mode

button is used for the fast selection of different programs.

The mixing paddle revolves at a rate of 140 rpm. with a

planetary motion of 62 rpm. in low speed. In high speed,

the paddle revolves at the rate of 285 rpm. with a

planetary motion of 125 rpm. An automatic sand

dispenser is supplied with the machine and the sand is

automatically discharged. Custom design allows 6

programs to be set by the operator, where the motor

speed, sand dispenser position and duration of the mix

can be set. For the mix where the motor speed is selected

as zero, the bowl can be lowered without interrupting the

rest of the program. On the display the user can see the

mix time and the machine is equipped with lamp in order

to warn the user for critical time periods.

The Automatic Programmable Mortar Mixer is supplied

complete with:

Bowl: 5 lt (approx.)

Beater

Dimensions: 300 x 555 x 610 mm

Weight (approx.): 56 kg

Power: 200 W

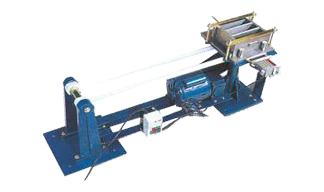

JOLTING APPARATUS

Specification:

The jolting apparatus consists of a rectangular table rigidly connected by two support arms to a spindle at a horizontal

distance of 800 mm from the centre of the table. There is a projecting lug with a plane face on the upper face of the

table beneath which is a stop with a rounded upper surface. The table can be raised and allowed to fall freely on the

stop by a cam which is connected to a motor and gearbox through a V-belt an pulleys. The cam

rotates at a rate of 60 Rev/Min. A stroke counter fitted with micro-switch is provided which stops

the machine after 60 Jolts. Locating pins are provided for mounting the mould compartments

on the table. The mould surmounted by the hopper can be clamped rigidly to the

table. Supplied complete with mould and hopper. Suitable for

operation on 230 Volts, Single Phase, A.C. Supply.

A Digital Preset Counter can be supplied at an extra cost.

Spares and Accessories :

(1) Steel mould with base plate having three compartments

each having 40 x 40 x 160 mm, internal dimensions.

(2) Apparatus for de-moulding the specimen.